Manufacturing Process

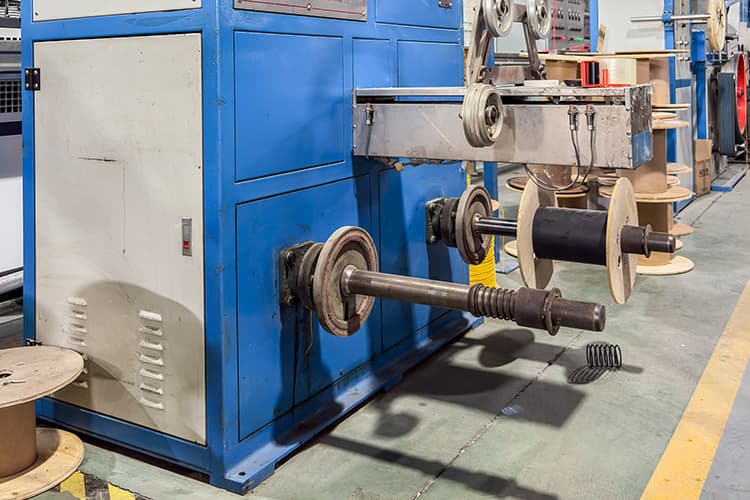

01. Optical Cable Production

We adopt advanced production processes and equipment, through precise manufacturing processes and strict quality control, ensuring that every optical cable product meets the highest quality standards.

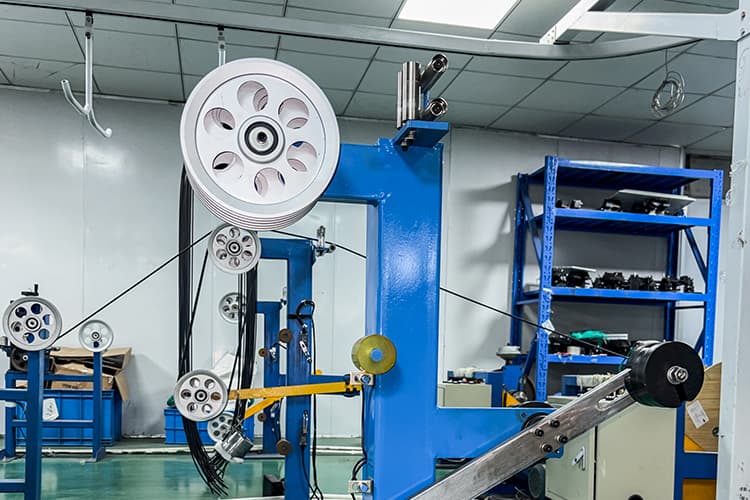

02. Jumper Cable Cutting

Using precise jumper cable cutting technology to ensure accurate cutting and end face quality of fiber optic jumpers, providing reliable guarantee for high-quality fiber connections.

03. Remote Drop Cable Cutting

Using advanced remote drop cable cutting technology to ensure cable cutting precision and efficiency, meeting production needs for various specifications of drop cables.

04. Component Assembly

Using fully automatic component assembly technology to ensure assembly precision and efficiency, meeting production needs for various specifications of fiber optic connectors.

05. Stripping and Trimming

Using precise stripping and trimming technology to ensure the cleanliness and quality of the fiber surface, providing a high-quality processing foundation for subsequent processes.

06. Fiber Stripping

Using high-precision fiber stripping technology to ensure accurate stripping of fiber coating layers, providing high-quality fiber end faces for subsequent connection processes.

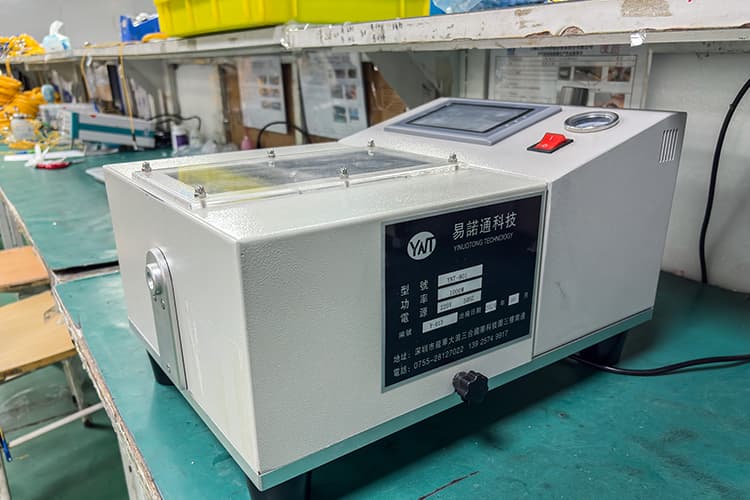

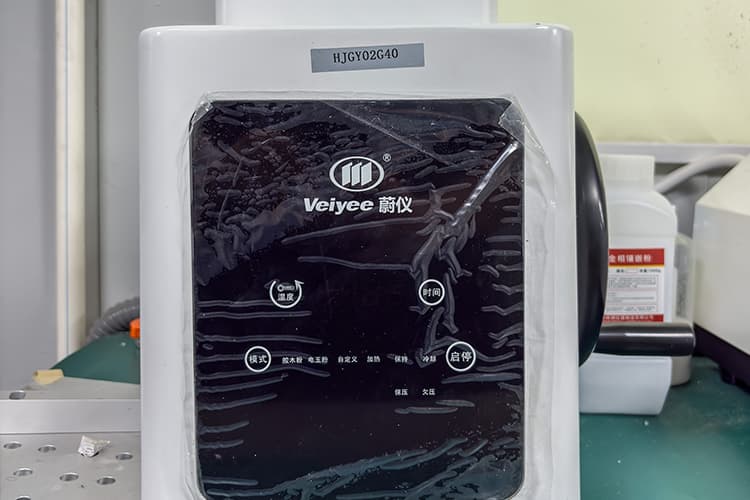

07. Adhesive Injection & Vacuum

Using advanced adhesive injection and vacuum technology to ensure connector sealing and reliability, improving product service life.

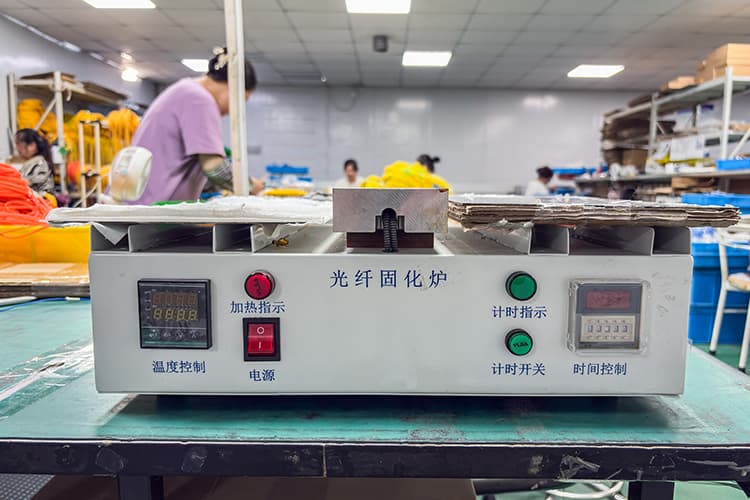

08. Curing

Through precise temperature control and time management, ensuring complete adhesive curing, providing stable connection strength and durability.

09. Crimping

Using precise crimping technology to ensure a firm connection between the connector and fiber, providing excellent mechanical strength and electrical performance.

10. Polishing

Through multi-stage polishing processes, precisely controlling the flatness and smoothness of fiber end faces, ensuring optimal connection performance.

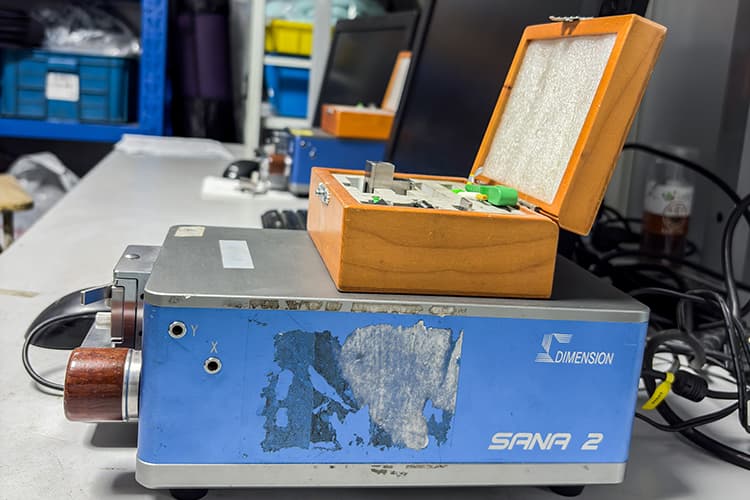

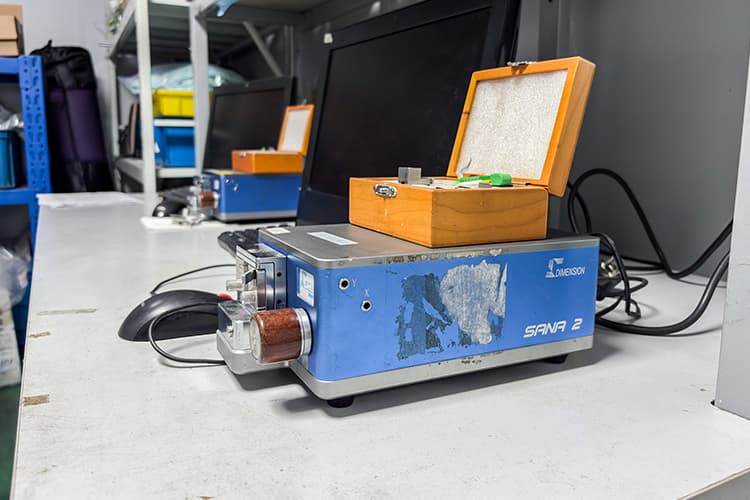

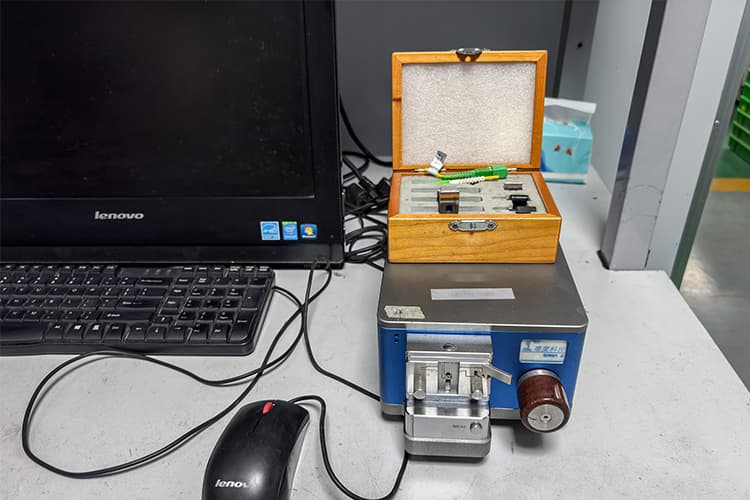

11. 3D Inspection

Using advanced 3D interferometry technology to precisely detect geometric parameters of fiber end faces, ensuring high-quality standards for connectors.

12. Tensile Test

Through professional tensile testing equipment, verifying the mechanical strength of connectors, ensuring product reliability under various environmental conditions.

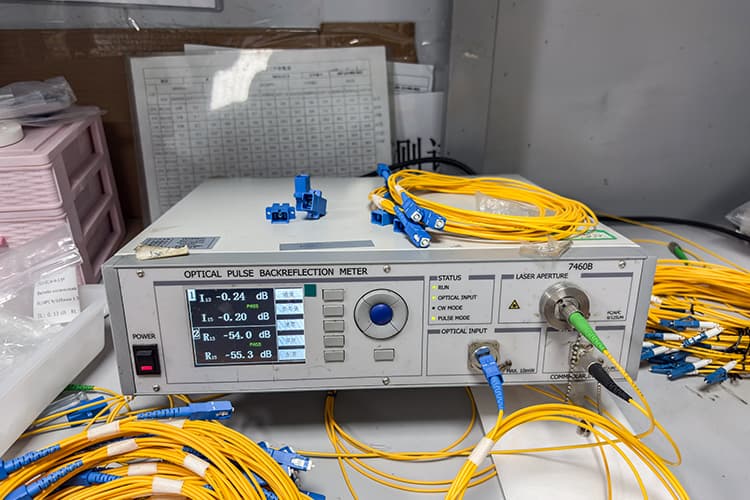

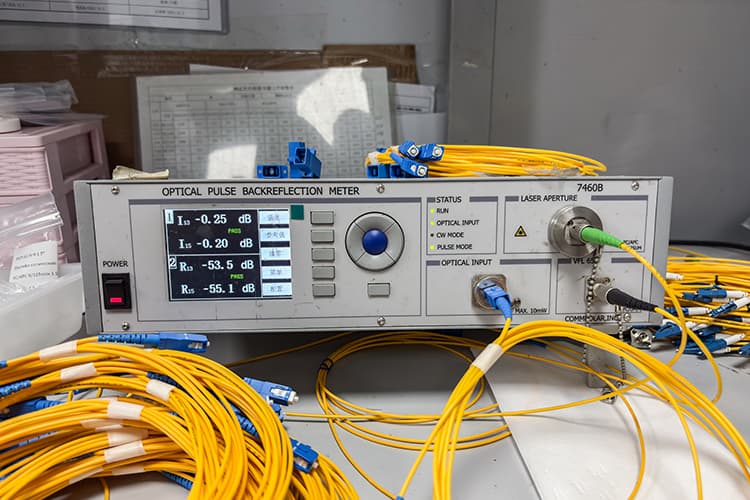

13. Insertion & Return Loss Test

Using high-precision testing equipment to measure insertion loss and return loss of connectors, ensuring optical signal transmission quality.

14. End Face Inspection

Using high-resolution end face inspection equipment to comprehensively check the cleanliness and integrity of connector end faces, ensuring product quality.

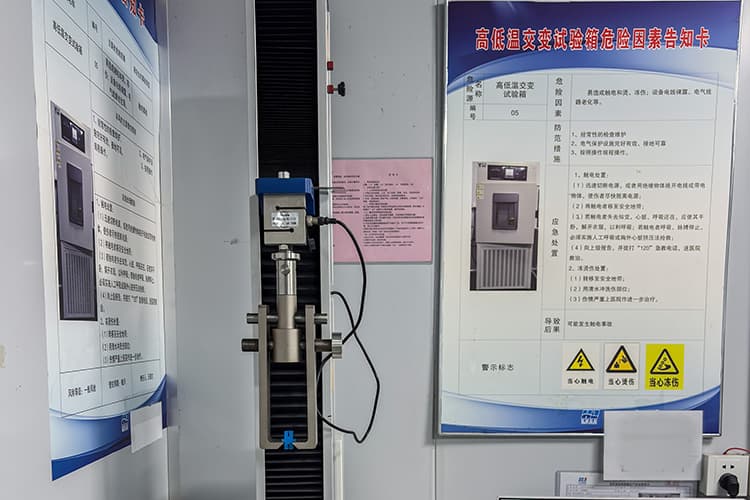

15. Environmental Test

Through high-low temperature alternating humidity and heat tests, verifying product stability and reliability under various extreme environmental conditions.

16. Ferrule Fatigue Test

Through professional fatigue testing equipment, evaluating the durability and stability of ferrules during repeated insertion and extraction processes.

17. Salt Spray Test

Through high-precision salt spray tests, evaluating product corrosion resistance under harsh environments, ensuring long-term use reliability.

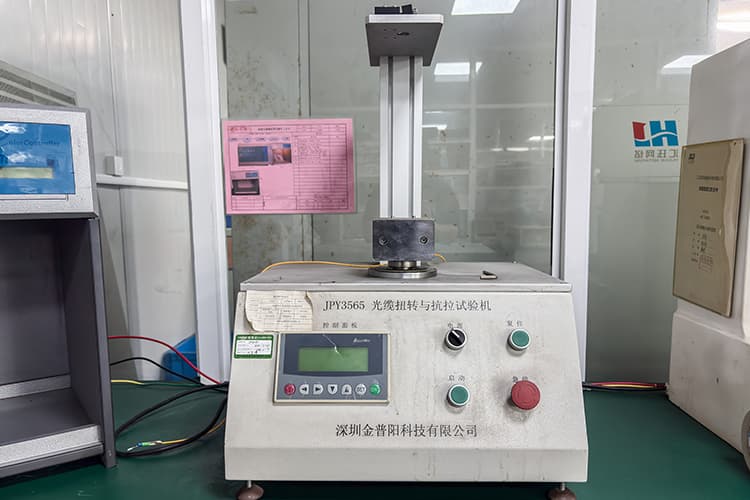

18. Cable Performance Test

Through professional torsion testing equipment, comprehensively testing the mechanical performance and transmission characteristics of optical cables, ensuring product quality.

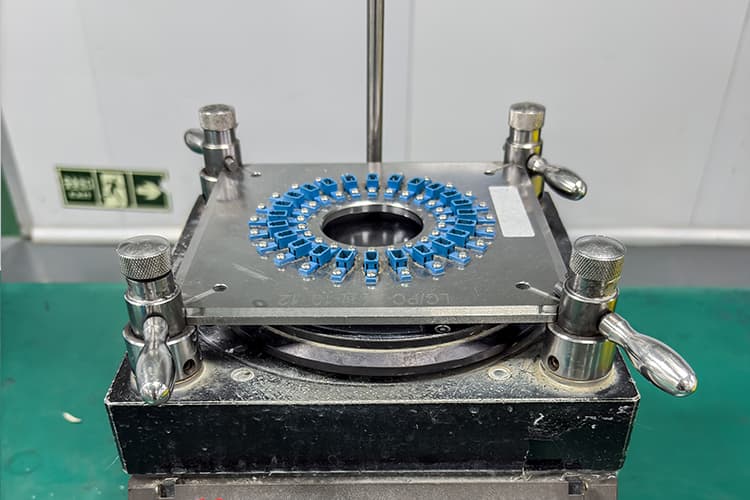

19. MPO Insertion & Return Loss & Polarity Test

Using professional MPO testing equipment to precisely measure insertion loss, return loss, and polarity of multi-core connectors, ensuring high-density connection quality.

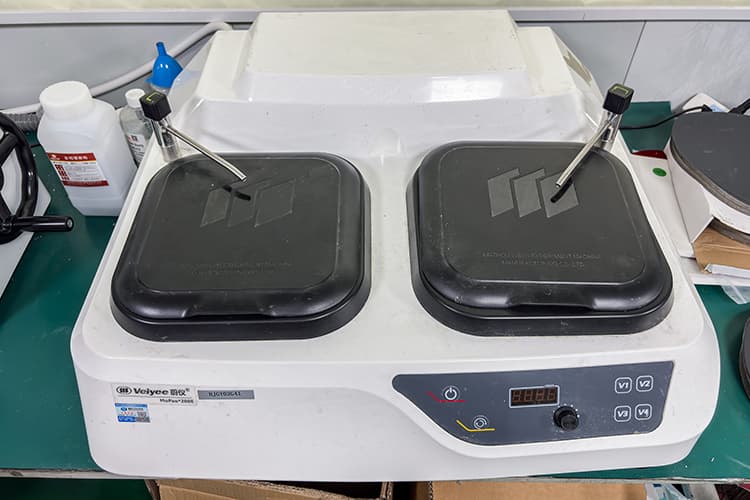

20. Ferrule Section Inspection

Through metallographic sample mounting technology, performing section inspection on ferrules, deeply analyzing internal structure and quality conditions.

21. Packaging

Using professional wire tying and winding equipment to standardize product packaging, ensuring product integrity during transportation and storage.

Manufacturing Process

Contact Us

Professional Passive Optical Component Solutions, Providing You with High-Quality Products and Services